the realm of industrial processes, effective management of ammonia systems is paramount for safety, efficiency, and compliance. Leveraging the power of Internet of Things (IoT) technology, in-house automation solutions are transforming the way organizations handle their ammonia-related operations. From real-time monitoring to predictive maintenance, IoT-enabled automation offers a comprehensive approach to optimizing ammonia management processes.

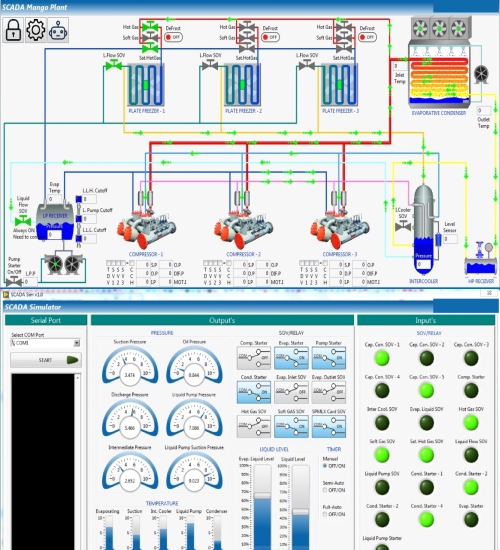

Real-Time Monitoring

Gain instant visibility into critical parameters such as ammonia levels, temperature, and pressure, empowering operators to make informed decisions in real-time.

Remote Access and Control

Seamlessly monitor and control ammonia systems from anywhere, at any time, enhancing operational flexibility and efficiency.

Predictive Maintenance

Leverage data analytics and machine learning algorithms to predict equipment failures and pro actively address maintenance needs, minimizing downtime and maximizing productivity.

Safety Compliance

Ensure adherence to safety regulations and standards by implementing automated alarm systems and emergency response protocols, safeguarding personnel and assets.

Energy Efficiency

Optimize energy consumption by analyzing operational data and implementing intelligent control strategies, reducing costs and environmental impact.

Sensor Integration

Utilize a variety of sensors to monitor key parameters such as ammonia concentration, temperature, pressure, and humidity.

Data Transmission

Employ secure communication protocols to transmit data from sensors to a centralized IoT platform for analysis and processing.

Cloud-Based Analytics

Leverage cloud-based analytics platforms to analyze large volumes of data in real-time and generate actionable insights for operational optimization.

Integration with Existing Systems

Ensure seamless integration with existing control systems and SCADA (Supervisory Control and Data Acquisition) infrastructure to enhance interoperability and efficiency.

Monitor and control ammonia-based refrigeration systems in cold storage warehouses to ensure optimal temperature and humidity levels for perishable goods.

Automate ammonia handling processes in food processing plants to maintain sanitary conditions and compliance with food safety regulations.

Implement IoT-based automation in chemical manufacturing facilities to optimize ammonia usage and enhance process efficiency while ensuring safety and environmental compliance.